In the modern day, the Fume extraction systems have been widely used across various industries, research laboratories and many other places. These fume extraction systems are significant options for easily taking care of the harmful fumes from the machines and chemicals. Installing the best fume extraction arm is one of the significant options for easily removing harmful gases and clearing the air.

There are many options available for clearing the gasses from the closed spaces. Fume extraction strategy involves the energy hogging equipment and many others for easily reducing the harmful gases.

What is the fume extraction strategy?

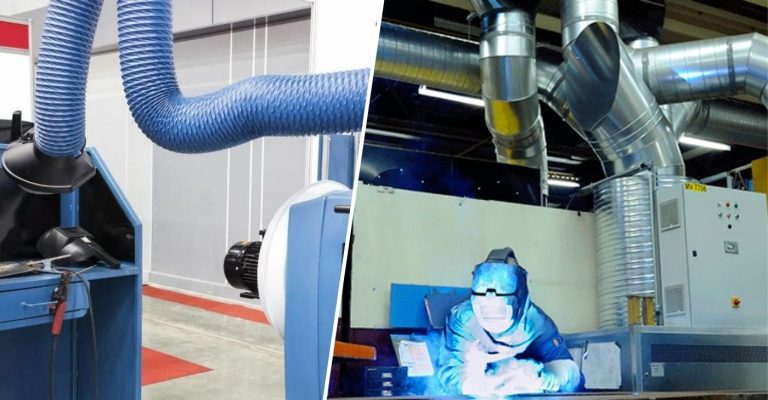

Fume extraction systems work by easily capturing and controlling the smoke, welding fumes as well as other airborne contaminants. These play a major role in protecting machine operators by removing the smoke.

Fume extraction systems are specially designed to capture harmful gases directly from the welding arc. These are unique source capture systems that also utilize the exhaust hood and blower. It would be suitable for extracting and drawing the contaminated air in the contained filtration system.

Implementing the Fume extraction strategy is a suitable option for cleaning and exhausting the air in the closed space. Fume arms are the source capture system that is effective in controlling air contaminants, welding fumes, smoke, and many others.

Normally, the Fume extractors are available in different configurations. These include extraction arms for controlling the overexposure to smoke. The Fumes generator is used during welding and other machining processes.

1. Conduct systematic industrial hygiene assessment:

Normally, there are no one-size-fits-all fume extraction solutions, so it is essential to choose the right Fume extraction system based on the configuration. There are also specific circumstances and variables in the welding operation that require unique choices.

Having a qualified professional in the industry is essential for conducting the systematic industrial hygiene assessment of worker exposures. Partnering with a well-experienced industry supplier would be suitable for getting a wealth of information.

These are significant for making the best decision on the extraction solutions for varied operations. Establishing the baseline measurement of worker exposure in the industry is essential before developing the fume extraction system.

Making the assessment from a qualified professional such as a Certified Industrial Hygienist is a significant option for choosing the right Fume extraction systems. Precise exposure data of the employees in the industry is helpful for easily setting the Fume extraction system with compound-based regulatory requirements.

Safety Data Sheets are also important for applying the welding operation. Hygienists could enlist the assessments to optimize the accuracy of the assessments by engaging the EH&S team.

2. Evaluate your welding process:

For effectively reducing the fume, it is essential to evaluate the right welding process. Various alternatives are available for the welding processes and shielding gases. These would extensively reduce welding fume generation and ensure the best result is provided.

Various methods such as the surface coatings such as paints need to be removed before making the cutting or welding. A proper respirator needs to be used to ensure the fumes are cleared from the closed spaces. When the fumes or airborne exposures are mixed with other coatings like corrosion-inhibiting compounds, then it would be harmful to the employee’s inhale.

Before choosing the Fume extraction system, it is important to evaluate the complete welding process. Many industries have been switching from FCAW to GMAW-pulsed and even to the CO2/argon/oxygen blend to get the complete solution.

Alternative options are also available, which help to identify the ways to reduce the welding generator fumes. The method could easily reduce the up-front costs of installing these extractors. Installing this equipment makes it easier to extract fewer fumes from the closed space.

3. Implement safe work practices:

One of the important attributes to follow is to evaluate and implement safer work practices. Normally, safety procedures need to be followed when utilizing the Fume extraction systems. Employees need to be completely trained in handling this equipment for effective fume extraction.

Improving the complete level of training and safety awareness of employees helps them to work safely in the atmosphere. Proper work practice needs to be followed by the welders or lab technicians. These would automatically reduce the impact of airborne exposure to the fumes.

Proper handling of the fumes from the machine with the Fume extraction systems saves more time. Utilizing the right Fume extraction systems is suitable for implementing safer welding work practices.

Normally, these efforts are enhanced by adding signage, posters, and many other things. Proper training about the workspace safety protocols and guidelines are helpful.

4. Choose the right fume extraction system:

In the modern day, there are many types of Fume extraction systems available with configurations and features. Incorporating the right Fume extraction system such as Ducted Fume hoods, Ductless Fume hoods or Spot Extractors would be helpful.

Ducted Fume hoods are useful for heavy fume-generating facilities. These are completely featured enclosures with varied utilities and flow control. Fume hoods are an important piece for user safety, and they are quite expensive compared to other models.

These have extraction arms in a variety of styles to easily reduce the fumes. Ductless fume hoods are the new generation having activated carbon filters. It is significant for removing the chemicals from the fumes along with re-circulating cleaner air in the space.

These Fume extractors have a simple plug-and-play mobile unit. These would easily reduce 70% less running cost when compared to the conventional fume hoods. Spot Extractors are also available with flexible arms with self-supportive features. These are flexible enough to move around in the space without restricting the view of operators.

Conclusion:

Implementing the Fume extraction strategy helps to easily and safely clear the air or fumes from the closed space. Examining fume extraction equipment and employee training on these equipment are essential for maintaining safety. Level of training with creating safety awareness is helpful during the operation. Safer work practice is potentially suitable for creating a large impact on fumes exposure.